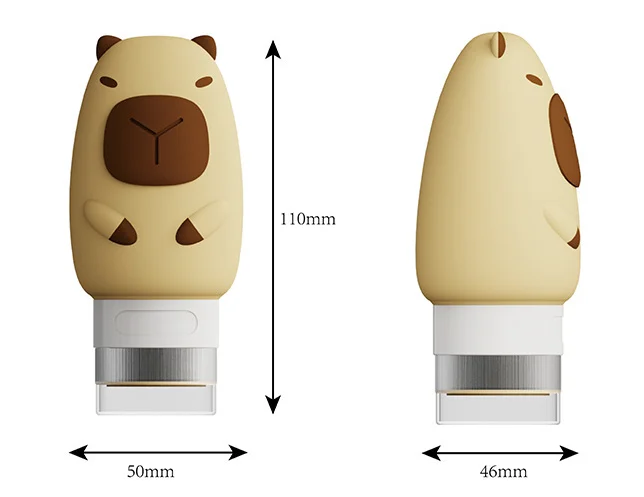

90ml Capybara Packaging Bottle High-Precision Food-Grade Silicone Travel Containers for Global OEM Brands

90ml Capybara Packaging Bottle High-Precision Food-Grade Silicone Travel Containers for Global OEM Brands - Advanced Analysis

Industrial Performance Engineering

In the global personal care market, inventory turnover is directly proportional to product reliability. Our Capybara Packaging Bottle system is engineered to solve the chronic issue of logistical fluid migration. Utilizing 100% food-grade Liquid Silicone Rubber (LSR), the chassis is molded as a seamless mono-body, eliminating weld-line failure points. This technical approach provides your brand with a high-retention accessory solution that reduces post-sale customer friction and maximizes brand prestige during high-altitude travel.

The precision-engineered internal “Cross-Slit Valve” serves as a primary air-return mechanism. Unlike traditional open-aperture caps, this vacuum-slit requires intentional physical pressure to evacuate formula, ensuring a hermetic seal even under extreme aircraft hold pressure variations.

Technical Verification Matrix

| Attribute Category | Measured Industrial Standard |

|---|---|

| Modelo | S-GS031 |

| Base Material Chassis | 100% Food-Grade Silicone (BPA-Free) + High-Tension PP Cap |

| Volumetric Displacement | 90ml / 3.0 fl.oz (Precise TSA Global Carry-on Compliance) |

| Physical Footprint | 110mm (Height) x 50mm (Width) x 46mm (Depth) |

| Structural Net Weight | 22.0g (Precision Molded for Logistics Cost Optimization) |

| Thermal Resilience | Resilient Performance from -40°C up to 220°C (Industrial Autoclave Safe) |

| Sanitary Certification | FDA 21 CFR 177.2600, LFGB Grade, REACH Approved |

| Wholesale MOQ | Standard Stock: 500 sets | OEM Pantone Match: from 1,000 units |

Competitive ROI Benchmark: Silicone vs. PET Plastic

Professional procurement managers recognize that “Initial Unit Cost” is often a distraction from “Total Lifecycle Value.” Commodity PET plastics suffer from Environmental Stress Cracking (ESC) and formula leaching. Our high-precision Capybara Packaging Bottle chassis ensures 99% chemical formula safety while providing a tactile “Soft-Touch” premium feedback that elevates the perceived retail value of your kit.

■ Commodity PET Plastic

Reliability Fatigue Stress Metrics

B2B buyers mitigate risk through technical data. We subject every production batch to intensive stress cycles to ensure zero customer complaints for your private label distribution. This visualization represents the actual “HP” (Health Points) of our hardware under industrial load.

Advanced 3-tier prevention: Reinforced threads, silicone gasket, and precision cross-valve. Passed 24-hour inverted pressure chamber testing without single drop migration.

Survives 200 lbs of static pressure. High-elasticity silicone walls act as kinetic shock absorbers during extreme cargo shifts or rough luggage handling.

Reinforced Polypropylene (PP) hinges tested for 10,000 consecutive robotic open/close cycles. Prevents accidental detachment during high-frequency refill cycles.

Global Channel Distribution Strategy

Understanding the end-user landscape helps procurement optimize turnover. Our contentores de viagem are balanced for high-turnover retail environments that require certified safety and premium tactile appeal. This data reflects high-performing sectors for wholesale distribution across Europe and North America.

- 40% Travel Retail: TSA-compliance volume demand at duty-free hubs.

- 25% Professional Gyms: High-frequency hygiene and shower usage.

- 20% Outdoor Retail: Extreme thermal resilience for camping demand.

- 15% Business Travel: Premium aesthetic differentiation for executive gifts.

Primary Scenario Reach

Data extrapolated from current global retail network performance indices.

Rapid OEM Customization Hub

Bespoke Color

Industrial Pantone matching for silicone bodies. High-dispersion pigments ensure brand consistency. Sample ready in 72 hours.

Identity Branding

Waterproof silk screening or permanent 3D in-mold embossing for a luxurious, tactile brand experience that resists peeling.

Mold Design

CNC proprietary mold development for unique brand silhouettes and ergonomic chassis modifications. Prototyping in 5 business days.

Retail Kits

Integrated retail solutions: Frosted EVA waterproof bags, high-clarity blister cards, or sustainable custom cardboard sets.

Bulk Source 90ml Capybara Packaging Bottle High-Precision Food-Grade Silicone Travel Containers for Global OEM Brands

Direct Factory Pricing | OEM/ODM Customization | GRS Certified Materials