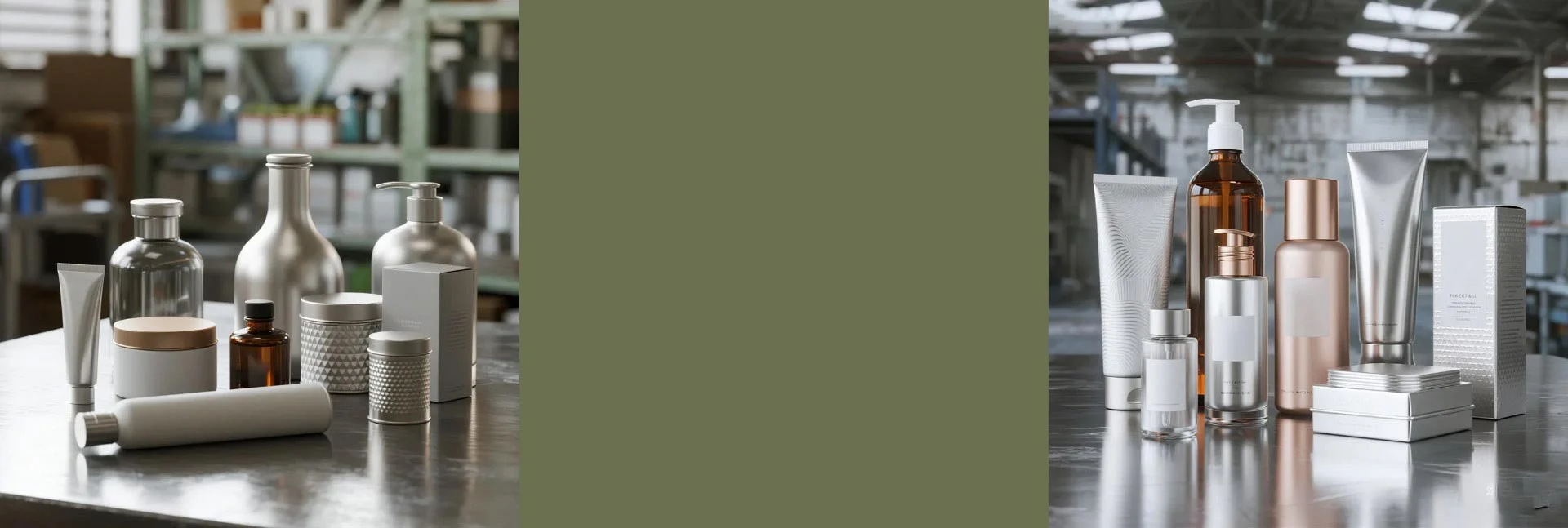

Custom Packaging Solutions

Direct From Factory

We engineer high-performance PE, PET, Aluminum, and Tinplate packaging for global brands. ISO-certified manufacturing with sustainable innovation.

Comprehensive Packaging Material Solutions

From flexible PE films to rigid Aluminum containers, we provide the raw material expertise and molding precision your brand needs.

Emballage PE

High-flexibility Polyethylene solutions including PE tubes, films, and squeeze bottles. Ideal for squeezable cosmetic tubes.

Explore PE Materials →

Emballage PET

Glass-like transparency with shatterproof durability. Food-grade PET for beverage and premium lotion packaging.

View PET Options →

Emballage en PP

High heat resistance and chemical stability. Perfect for cream jars, caps, and closures requiring rigidity.

Discover PP Solutions →

Emballage en aluminium

Lightweight, rust-proof, and 100% recyclable. Specialized for aerosol cans and premium screw-top bottles.

Aluminum Capabilities →

Emballage en fer-blanc

Robust steel packaging with tin coating. The standard for food preservation cans and industrial chemical containers.

Tinplate Products →Emballage en silicone

BPA-free, soft-touch material. Widely used for travel tubes, baby products, and sealing components.

Silicone Innovation →Engineering the Perfect Package: Material Science & B2B Selection Guide

In the competitive landscape of global FMCG, the choice of packaging material—whether it be PE (Polyéthylène), PET (polyéthylène téréphtalate), or metal alloys like Aluminium—dictates not only the shelf appeal but the logistical viability of the product. As a source manufacturer with over 15 years of injection and blow molding experience, Golden Soar moves beyond simple supply; we offer technical consultation based on material viscosity, chemical compatibility, and barrier requirements.

1. Density & Barrier Properties: PE vs. PET

For procurement managers deciding between plastic substrates, understanding the permeation rate is critical. Emballage PET offers superior oxygen barriers, making it the industry standard for oxidizable formulations like Vitamin C serums or carbonated beverages. Conversely, HDPE (High-Density Polyethylene) provides excellent moisture barriers but lower oxygen resistance, making it ideal for shampoos, laundry detergents, and household chemicals where water retention is key.

2. The Metal Advantage: Aluminum Aerosols & Tinplate Cans

When pressure resistance is non-negotiable, metal packaging dominates. Our Aluminum aerosol cans are manufactured using advanced impact extrusion, creating a seamless monoblock structure capable of withstanding internal pressures up to 18 bar. For the food industry, our Tinplate solutions utilize food-grade internal coatings (BPA-Ni options available) to prevent metal migration, ensuring extended shelf life for perishable goods. The shift towards “infinite recyclability” has made aluminum the preferred choice for eco-conscious luxury brands.

3. Cost-Efficiency in Molding Processes

Mold cost amortization is a major factor in unit economics. While injection molding (often used for PP jars and complex caps) requires higher initial tooling investments, it offers the lowest per-unit cost at scale. Extrusion blow molding (for PE bottles) offers faster tooling lead times. At Golden Soar, we analyze your annual volume projections to recommend the process—Injection, Extrusion, or Injection-Stretch-Blow-Molding (ISBM)—that yields the highest ROI.

Industry-Specific Applications

Personal Care Series

We supply high-volume solutions for shampoo, body wash, and hair care. Our PE and PET bottles feature ergonomic designs and compatibility with various pump systems.

- • Soft-touch finishes available

- • High-output dispenser pumps

- • Custom color matching

Skincare & Cosmetic Packaging

Elevate your brand with our precision-molded PP jars and airless bottles. Designed to protect sensitive active ingredients from oxidation.

View Skincare

Medical, Healthcare & Daily Use

From aluminum aerosol cans for sanitizers to pharmaceutical-grade pill containers. We ensure strict hygiene standards in production.

View Medical Solutions

Food Cans & Preservation

Safe, durable tinplate packaging for dry foods, nutritional powders, and beverages. Internal coatings available to meet FDA/EU food safety regulations.

View Food CansManufacturing Process Visibility

Transparency is our policy. Watch how we transform raw aluminum, tinplate, and plastics into world-class packaging.

Frequently Asked Questions (B2B Procurement)

Have more questions?

Visit Full FAQ CenterReady to Scale Your Packaging Production?

Join 10,000+ satisfied clients. From concept to container, we are your partner.

Request A Quote