Stop Selling Containers.

Start Building Ecosystems.

In a world drowning in single-use plastic, the brands that win aren’t just “recyclable”—they are **indispensable**. Golden Soar’s Refillable Systems (Multi-use) allow B2B brands to decouple the high-value brand asset (the outer shell) from the consumable pod. It’s the ultimate B2B strategy for locking in high-margin repeat orders while slashing net plastic waste by over 70%.

The Math of “Saying No to Single-Use”

Let’s speak human: Why should a B2B procurement manager switch? Traditional luxury packaging is “Heavy Trash.” A standard 50ml acrylic jar weighs 180g. If your customer buys 12 jars a year, they throw away **2.16kg of plastic**. With our refill system, they buy the 180g shell **once**, and 11 refill pods at 25g each. **Total plastic: 455g.**

Cumulative Plastic Waste (12-Month Cycle)

*Calculation based on 50ml Luxury PMMA Jar vs. Mono-material PP Refill Pod.

The 72% Advantage

By switching to a refill architecture, you instantly reduce the raw material consumption of your repeat orders by 72%. This isn’t just about saving the planet—it’s about optimizing your **BOM (Bill of Materials)** and drastically reducing international shipping costs for your heaviest component.

Engineering the Perfect Fit

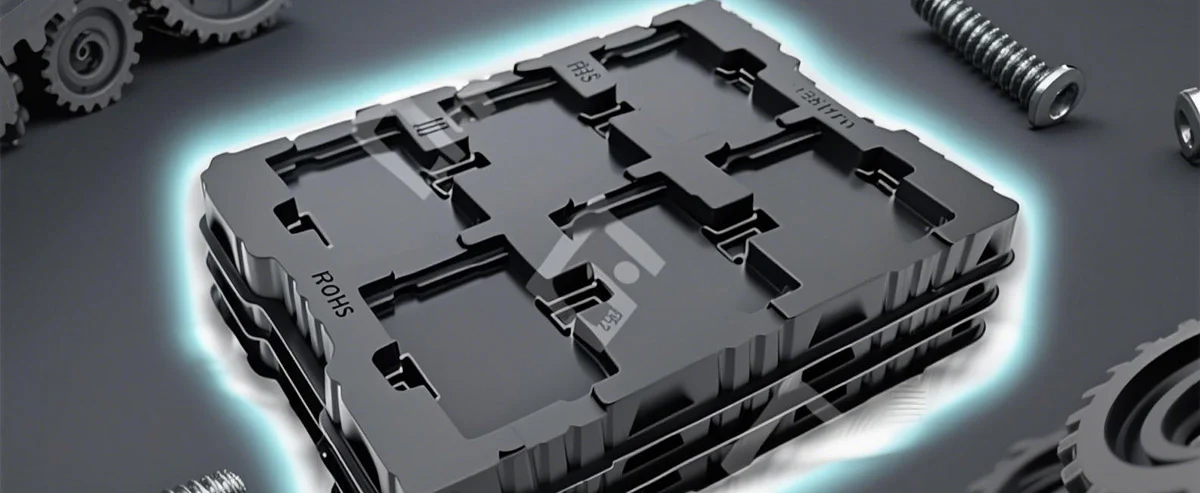

A refillable system is only successful if the “Swap” feels premium. We utilize **Scientific Injection Molding (SIM)** to maintain tolerances of ±0.03mm. If the inner pod is too loose, it rattles and feels cheap. If it’s too tight, the consumer can’t remove it. Our system ensures a satisfying “Click” every time.

Figure 1: Decoupling the Shell (Asset) from the Pod (Consumable).

How the Multi-use Loop Works

Packaging UX (User Experience) is about frictionless habits. Our designs prioritize the “Swap” as a moment of brand interaction.

Twist & Remove

The consumer twists the inner pod 45 degrees. Our “Quick-Release” thread allows for tool-free removal even with oily hands.

Drop & Click

The fresh refill pod drops into the rebate. Precision guiding ribs ensure perfect alignment with the pump engine.

Seal & Use

The user peels off the secondary induction seal. The formula has never touched the outer chassis, ensuring 100% hygiene.

Industrial Comparison: B2B Decision Matrix

| Metric | Standard Single-Use | GS Refillable System | Business Impact |

|---|---|---|---|

| Consumer Retention | Low (Disposable habit) | High (Subscription loop) | Increased CLV |

| Plastic Tax Exposure | 100% Volume Taxed | Pod-only (Minimal Tax) | Lower OpEx |

| Branding Real Estate | Discarded in 30 days | Stays on vanity for 3 years | Passive Marketing |

| Recycling Ease | Hard (Complex assembly) | Easy (Mono-material Pod) | CSR Compliance |

Advanced Airless Refill Modules

For sensitive serums (Vitamin C, Retinol), oxygen is the enemy. Our Replaceable Airless Bottles use a vacuum-piston mechanism inside the pod. This ensures that even during a refill swap, the formula remains 100% protected from oxidation.

Micro-Science: The CPK Quality Guarantee

We track the **CPK (Process Capability Index)** of our mold cycles. A CPK of 1.33 means that 99.99% of our refill pods fit your outer shell perfectly. This industrial reliability is why global FMCG giants trust Golden Soar for their circular packaging transitions.

Refillable Systems FAQ

Are refillable systems more expensive initially?

How do you handle hygiene and contamination?

Can I customize the shape of the outer chassis?

What is the MOQ for custom refillable systems?

Is the inner pod truly recyclable?

Are these systems leak-proof for e-commerce?

How do I transition my existing product line to refills?

Transition to Circularity Today

Don’t wait for plastic taxes to eat your margins. Request a “Refillable System Engineering Kit” to test fitment, tactile feedback, and material clarity.

Request A Prototype Kit